Our Services

FIELD SERVICE

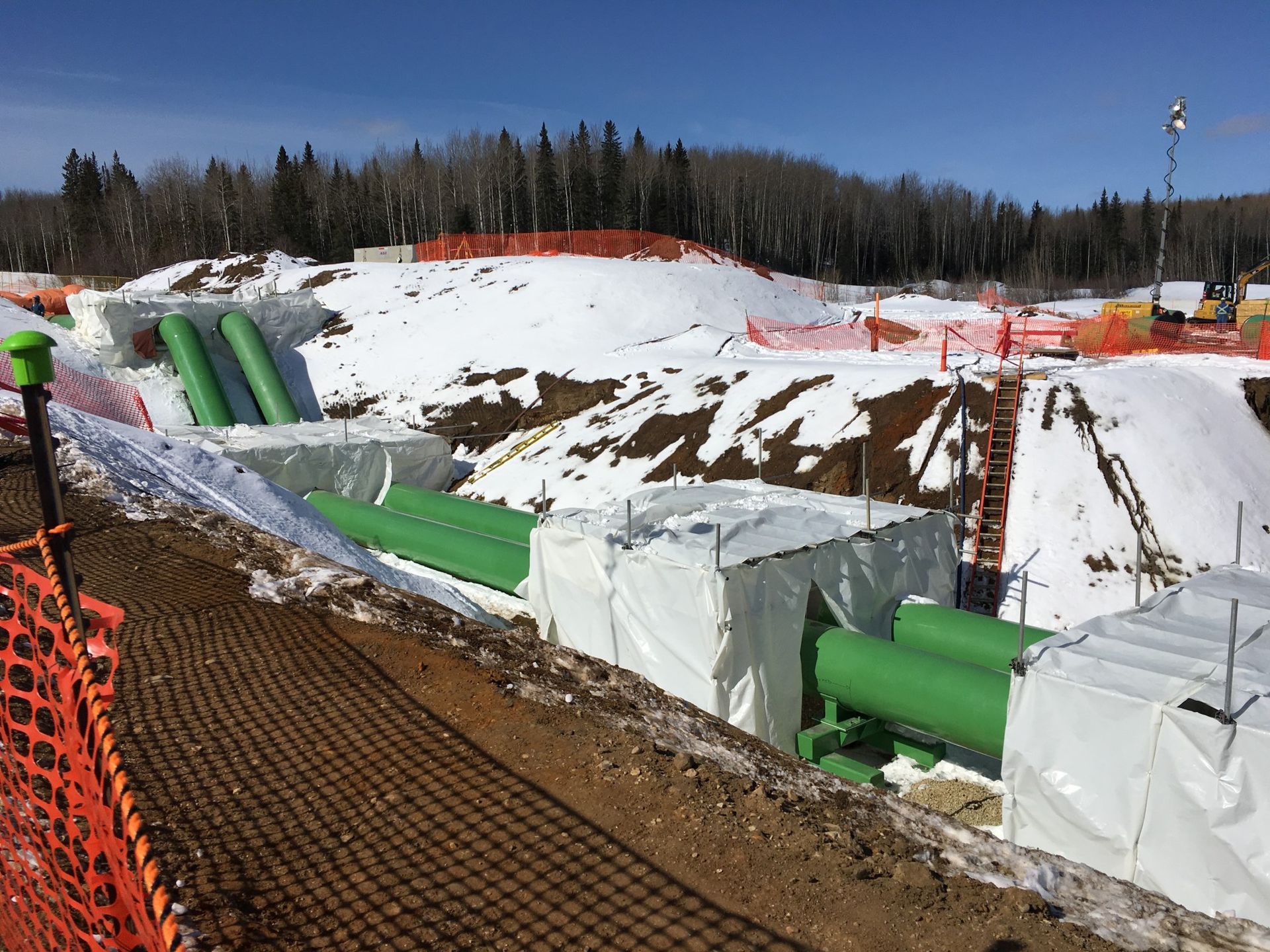

At Norpoint we provide the same high quality standards of our shop environment in all of our field services. Our comprehensive field services allow us to reach beyond our home base of Edmonton, Alberta and provide services across Western and Northern Canada.

Assess and Strategize

We assess the needs of our client and develop the correct strategy before deploying the necessary equipment and highly-trained personnel.

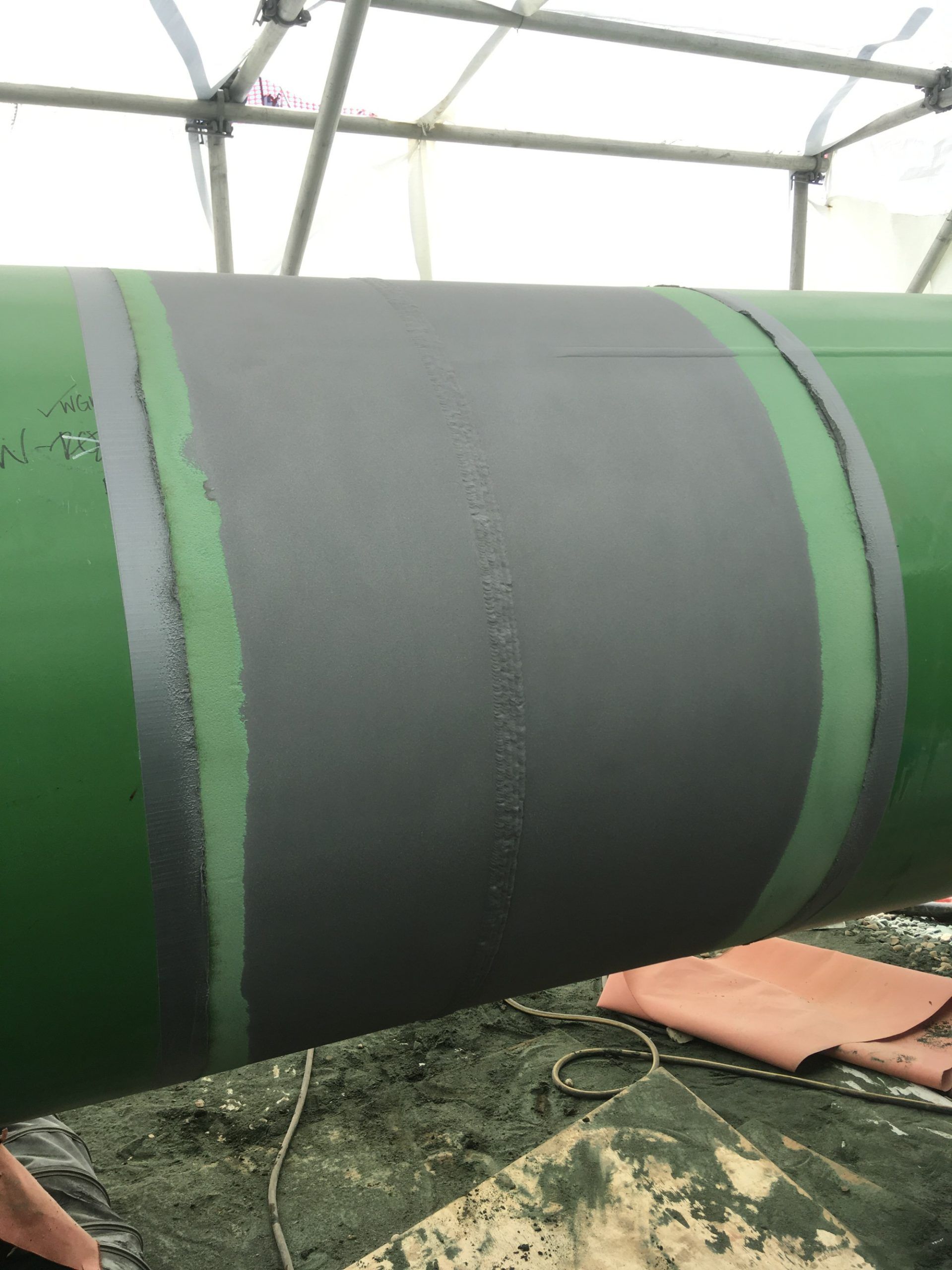

Norpoint is certified CSA Z245.30 compliant. This competency assured qualified application, inspecting, testing, handling, and storage of materials required for coating applications on buried or submerged piping inside a shop environment and in field locations. Our applicators receive training, complete qualification, and provide logs which are inspected, verified, and certified as compliant.

Our team includes many AMPP Certified Coating Inspectors (Formerly NACE Certified Inspectors), including Level 2 and Level 3. Norpoint is also an approved applicator for most major transmission Pipeline companies such as TC Energy, Enbridge, Pembina, Interpipeline, CNRL, Suncor, Syncrude Canada and PCL Industrial.

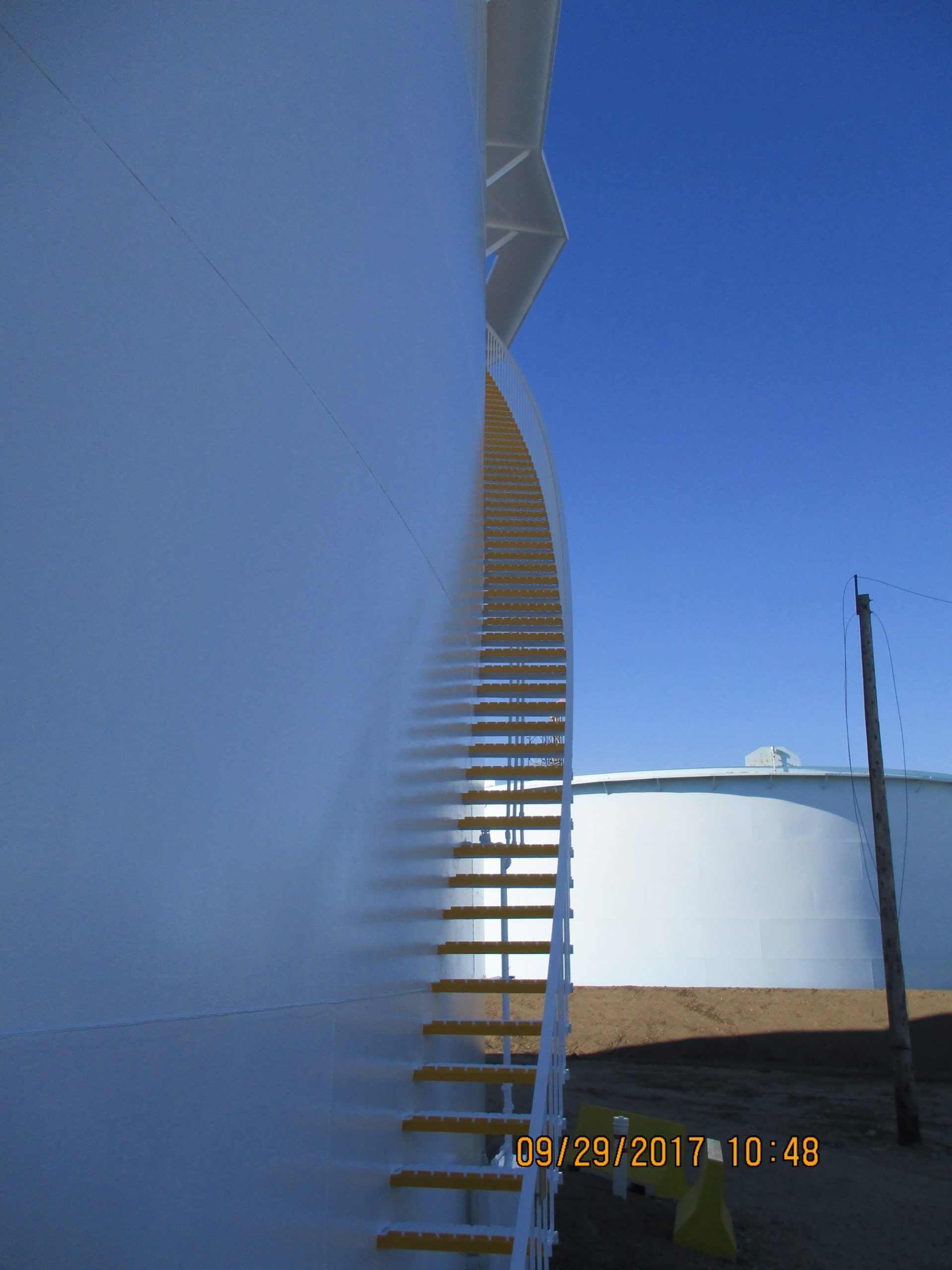

Our field services provide helpful solutions for maintenance, new construction, and shutdown work commonly used in:

Pipe Lines (New Construction and Maintenance)

Integrity Digs

Storage Tanks (Internal and External)

Vessels (Internal and External)

Piping Below and Above Ground

Structural Steel

Complete Plant and Facility Work & Wet Abrasive Blasting

Blast Recovery System (BRS)

COMPLEX COATINGS SIMPLY DELIVERED

SHOP SERVICE

Our main facility is located in Leduc County, just west of Nisku, in Calmar Alberta, Canada. We offer convenient access to major roadways and thoroughfares allowing for timely and easy shipments for our customers.

Streamlined Process

The flow-through design of our facility allows for efficient and safe transport of products within all stages of application. Our trained operators move products by crane through out facility, from blast cleaning to painting and applications areas. All of our shop products are completed indoors ensuring faster turn-around times.

Modern Workshop

• Over 13,000 sq ft of production space

• Dedicated Department Offices

• 45’ coating shop height

• Over 35’ hook height and over 37’ foot crane bridge

• 30’ 6” wide shop door opening, 33’6” shop door height

• Two overhead cranes with 20 Tonnes lifting Capacity, and Unlimited lifting Capacity when using mobile cranes inside the shop

• Mobile Forklifts, Loader, Manlift & Shunt Truck

• Electric Air Compression

• Media Recycling Available

We specialize in:

Module Fabrication

Piping System Components and Pipe Spooling

Over Dimensional Skid Packages

Vessels, Tanks and Spheres

Valves and Valve Assemblies

Structural Steel

Automated Internal Blasting (PRD)

Internal Linings

COMPLEX COATINGS SIMPLY DELIVERED

We are industrial abrasive sandblasting, coating and lining specialists.

All Rights Reserved | Norpoint | Privacy Policy